Electric Contacts

-

Products

- Information

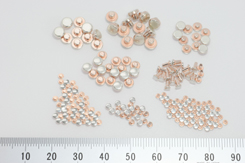

Electric contact for on-vehicle

Characteristics

- Line up of a reliable cadmium free contact which can be applied to a relay, a switch, an electromagnetic switch, etc, is prepared.

Application

- Examples in Introductions/Achievements This contact is mainly used for an on-vehicle electric relay or switch. In addition, this contact is used for high voltage applications, e.g., a hybrid car, etc.

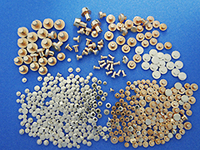

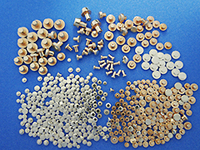

Electric contact for home electric appliances

Characteristics

- Line up of a reliable cadmium free contact which can be applied to a relay, a switch, an electromagnetic switch, etc, is prepared.

Application

- Examples in Introductions/Achievements This contact is used for a relay, a switch, a connector, a breaker and a protector in a home electric apparatus, a power distribution apparatus, a control apparatus, etc.

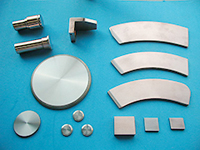

Electric contact for Electric power

Characteristics

- This contact is a particular composite alloy having both of high conductivity and arc resistance. This composite alloy is produced by compositing a high melting point metal excellent in arc resistance, and durability, e.g., tungsten, tungsten carbide, or the like with a high electric conductive and high thermal conductive metal of Ag and Cu by a powder metallurgical process. This contact is used as various contacts for an electric power.

Application

- Examples in Introductions/Achievements This contact is widely used as an electric contact in heavy load applications in a power receiving/distributing substation, e.g., various power breakers (in vacuum, oil, atmosphere, and gas), a pole switch, a tap switch, etc.

Electrode

Characteristics

- This electrode is a particular sintered composite material of tungsten and silver or copper, and is for an electrode material for an electric discharge machining more excellent in consumption resistance, working speed, and workability, and cutting-machinability than a general copper-based electrode material. This electrode is useful for electric discharge machining with high accuracy and high efficiency.

Application

- Examples in Introductions/Achievements Electric discharge machining electrode

- Products

Information

For further details of our products, please feel free to contact the sales department of our Company.

NIDEC MATERIAL CORPORATION Sales Department

| 46-1, Senpuku, Susono-city, Shizuoka 410-1116, Japan |

|---|

| Tel:81-55-992-6111 Fax:81-55-992-6140 |